The Advantages of Automated Pharmaceutical Packaging Inspections

Date: July 20, 2021 | Category: Proofreading | Author: Kayla Caticchio

The Benefits of Automated Pharmaceutical Packaging Inspections

Automated pharmaceutical packaging inspections have revolutionized the pharmaceutical industry by enhancing the efficiency, accuracy, and safety of the drug manufacturing process.

As the demand for pharmaceutical products continues to grow globally, ensuring the quality and integrity of drug packaging is of critical importance. In this increasingly complex and highly regulated sector, automation plays a pivotal role in addressing the challenges of quality control and compliance.

From reducing human error, streamlining the production process, and contributing to the delivery of safe and effective medications to patients worldwide, the advantages of automated pharmaceutical packaging inspections are endless, bringing added benefits to any pharmaceutical company looking to elevate its quality assurance processes.

The Benefits of Automated Pharmaceutical Packaging Inspections

Packaging Inspections

The automated inspection of pharmaceutical packaging has become essential to the day-to-day affairs of companies wishing to attain the efficiency and error-free work that is demanded of them. In addition to the rigorous quality control implemented on the products themselves, it is important to ensure the compliance of packaging and labeling information.

According to the Institute of Medicine, labeling and packaging issues were the leading cause of medication errors, reaching upwards of 33%.

If labels and packaging components are not up to the same quality standards as the products themselves, there could be detrimental consequences to both the brand and the consumer.

Automated Packaging Inspection Technology: An Essential Tool for Pharma

Quality control is at the forefront of any successful enterprise and automation is one of the best ways to achieve a strong quality control process. Automated quality inspections are more accurate and efficient than manual proofreading. The role of automation within a company’s operating processes will dramatically improve the prevention of packaging errors and the number of potential recalls.

Here are only some ways that automated packaging inspection technology can help quality assurance teams in pharmaceuticals.

Advantage #1: Regulatory Compliance

Pharmaceutical companies are subject to stringent regulations and quality standards. Compliance with these regulations is non-negotiable, as it ensures that drugs meet the required safety and efficacy standards.

Automated packaging inspection technology helps companies meet these standards by providing consistent, objective, and traceable quality control processes. It can detect even the tiniest defects or discrepancies in packaging materials and labeling, allowing manufacturers to address issues before they result in costly recalls or regulatory penalties.

“With one pharmaceutical client, we had six complaints about missing text or periods last year. This year, we’ve had none since we installed the software. Up to now, we’ve saved 30 production runs, where there were missing periods. Thanks to the system, we were able to detect them in time.”

- Véronique Fortier, Quality Supervisor Labelink

Advantage #2: Minimizing Human Error

The pharmaceutical industry is highly sensitive to human errors, which can have grave consequences. Manual inspection processes are prone to inconsistencies and fatigue, making them less reliable for ensuring product quality.

Automated inspection technology, on the other hand, operates with precision and consistency, reducing the risk of oversight or error. This minimizes the chances of defective products reaching the market and, ultimately, patients.

“GlobalVision has been vital in artwork development as it helps pick up the tiniest of errors and differences both within text and graphics. It also saves so much time by not having to do manual proofreading.”

- Praenisha Ramnath, Pharmacovigilance & Compliance Manager at iNova Pharmaceuticals

Advantage #3: Improved Efficiency

Automated packaging inspection technology is not only more accurate but also significantly faster than manual inspection processes. It can analyze and assess a high volume of products in a short amount of time, mere minutes, and contributes to increased production efficiency. This not only saves time but also lowers production costs by reducing the need for manual labor and rework due to errors.

Advantage #4: Enhanced Product Quality

Automated systems can detect a wide range of defects or issues that might be challenging to identify through manual inspection, such as graphic errors, color deviations, errors in braille, barcode errors, label misalignments, and much more. This results in higher product quality and safety, benefiting pharmaceutical companies and patients.

“GlobalVision has reduced frustration, and there is less risk of customers rejecting packaging because of a print error.”

- Mr. Van der Klis, Head of Graphics Print Preparation at Smurfit Kappa Group

Advantage #5: Data Documentation and Traceability

Automated inspection systems generate detailed data and reports, providing a clear record of the inspection process. This traceability is invaluable for pharmaceutical companies in demonstrating compliance with regulatory requirements and improving their overall quality control processes.

Advantage #6: Cost Savings

While the initial investment in automated packaging inspection technology can be significant, it offers a substantial return on investment in the long run. The reduction in human error, increased production efficiency, and fewer recalls all contribute to cost savings and improved profitability for pharmaceutical companies.

“Clients are always looking to be more efficient with their budget. With GlobalVision, we’re able to do more work within the same time, meaning they’re getting more for their dollar.”

- Kyle Richards, EVP, Executive Director, Editorial, at IPG Health

Automation technology is currently being used in various manufacturing and production environments within pharmaceutical companies, helping them to stand out from the competition by ensuring top-quality products and packaging components. Aside from reducing the risk of errors, automation technology helps pharmaceutical companies save impressive amounts of time and money by eliminating the inefficiencies associated with manual proofreading.

How GlobalVision’s Automated Inspection Technology Produces Error-Free Pharmaceutical Packaging

Many prominent multinational companies operating in heavily regulated sectors have not yet embraced modern technologies designed to enhance workflow efficiency.

In certain instances, these organizations continue to depend on manual and labor-intensive proofreading and review processes that are prone to errors, presenting significant opportunities for workflow enhancements and optimization.

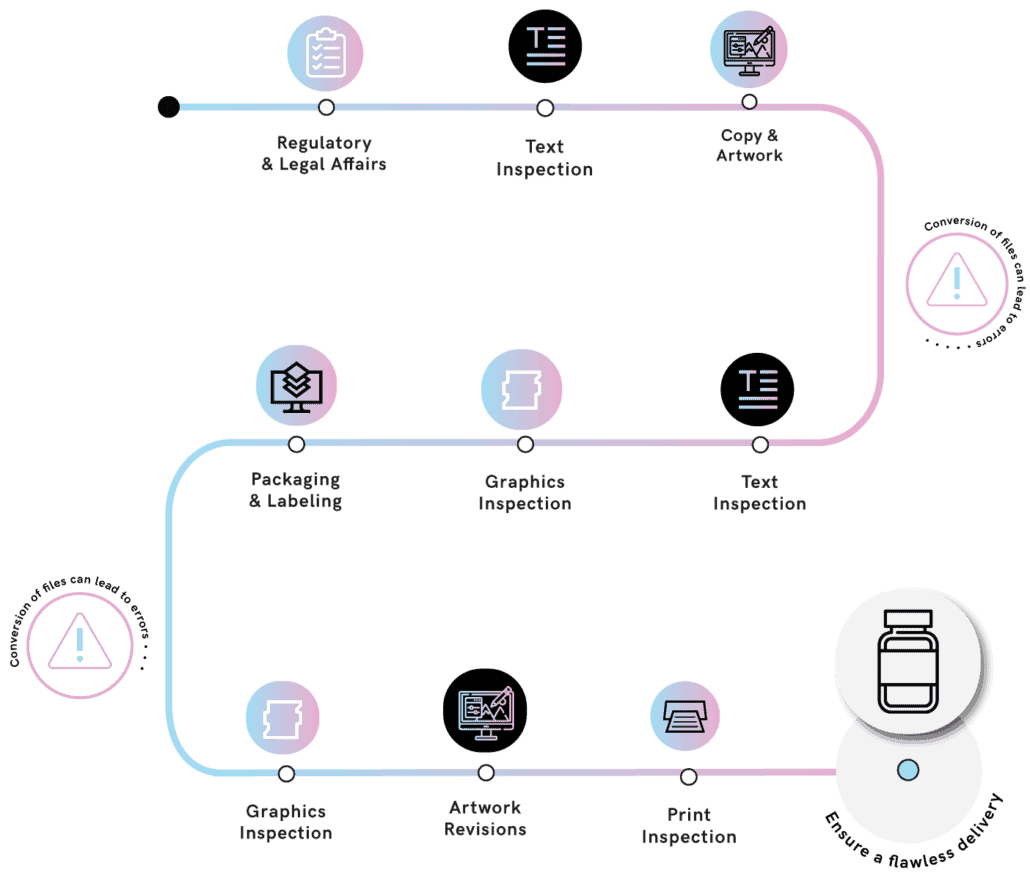

GlobalVision’s quality control technology was developed to meet the needs of regulated industries, particularly pharmaceutical and life sciences. The advantages of pharmaceutical packaging inspections do not stop solely at the reduction of risks pertaining to recall and error.

In fact, the benefits continue to include:

- Standardized verification of quality control at every stage of the pharmaceutical workflow

- The ability to track all revisions and changes between departments with full transparency

- Decreased labor costs thanks to the ability to expedite projects and proofread labels without delay

- Peace of mind knowing that any critical errors are caught before they inflict any sort of damage

Automated inspection technology inspects critical content and artwork with complete ease, lightning speed, and increased accuracy. To keep up with increasing global demand, regulated industries create an immeasurable amount of products, each with its own packaging, labeling, and documentation. This content must be meticulously reviewed and proofread to ensure the final product is error-free.

Manually proofreading all of this content is simply not an efficient solution for companies that want to remain competitive. Automated inspection technology offers a foolproof solution to ensure all this generated content is checked and proofread perfectly.

It’s important to note that pharmaceutical labeling is just as important as what’s included within the packaging. With the safety of consumers on the line, the best way to ensure label and packaging compliance is through the automated verification of these components.

This advancement in proofreading processes eliminates the need for manual document inspections and conducts digital checks for discrepancies in text, spelling, graphics, color, and more. The software conducts thorough inspections in a fraction of the time and ensures that labels and content are 100% accurate before going out to the hands of patients and consumers.

Automated inspection technology ultimately increases productivity and workflow efficiency and offers endless benefits unmatched by manual inspections. Not only does automation help ease the proofreading process, it simply makes proofreading and therefore your labels and packaging, better.

Conclusion

Automated pharmaceutical packaging inspections have created a new era of efficiency, accuracy, and safety within the pharmaceutical industry. In a global climate where the demand for pharmaceutical products continues to rise, the role of automation in ensuring quality control and compliance cannot be overlooked.

The advantages of automated packaging inspections are multifaceted, ranging from safeguarding regulatory compliance to minimizing human error, improving efficiency, and enhancing product quality.

The benefits of this technology extend beyond error detection and correction. This innovative technology offers standardized quality control, transparent revision tracking, labor cost savings, and, ultimately, peace of mind.

With the pharmaceutical industry’s reputation and the safety of patients at stake, automated inspection technology emerges as an essential tool, revolutionizing how pharmaceutical companies ensure error-free packaging and labeling, ultimately promoting a higher standard of quality and safety for all stakeholders involved.

Visit GlobalVision’s pharmaceutical page to learn more about how automated inspections can help your business bring confidence to quality control.

If you are ready to start reaping the benefits of automated quality control immediately, head to our Demo Center to learn about GlobalVision’s innovative inspection software and see firsthand how this technology can transform your regulatory quality assurance processes.

Related Articles:

- 5 Common Packaging Mistakes in Pharma

- Pharmaceutical Trade Tips for the Printing Industry

- Get your Complete Guide to Meeting FDA Labeling Requirements Here

- Streamlining Pharmaceutical Artwork Management

- Learn How Some of the World’s top Pharma Companies have Cracked the Efficiency Code with Automation

- Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

- Keep up with the latest updates in automated quality control. Sign up for our newsletter.