10 Ways to Improve Your Barcodes

Date: December, 2018 | Category: Proofreading | Author: Ryan Szporer

It’s a bit of a conundrum in our technologically advanced day and age, but, without barcodes to scan, the retail world would effectively grind to a halt. The dependency is understandable though, as barcodes are just that much more effective relative to labels, they can contain that much more information. It makes sense then that companies would want to ensure the barcodes they place on their products are perfectly functional.

10 Ways to Improve Your Barcodes

1. Choose the Right Type of Barcode

There are many different symbologies (types) spread across one-dimensional (1D) and two-dimensional (2D) barcode categories. Logically speaking, not all of them will be good fits for your specific needs as a company looking to go to market. Just to illustrate that fact, 1D or linear types typically serve to code small amounts of text, while two-dimensional types can hold upwards of 4,000 text characters or 7,000 digits.

As a result, a list of the different types and their respective functionalities are worth considering here, along with how much space with which you have to work on the packaging. For example, EAN-8 barcodes, which contain a relatively minimalistic eight digits, are used on packaging with limited space. Size also enters into the equation as barcodes get printed in larger sizes to improve their readability and compensate for certain surfaces’ poor quality.

2. Make Your Barcodes the Right Size

There’s generally a balance between printing accuracy, where larger is better, and ease of scanning, where too large can pose a problem. On the other hand, barcodes can get as small as one 1/8 in2, but special printer considerations would have to be taken in such an instance so each element remains readable.

Furthermore, reducing the height of a barcode (or truncating it) may seem smart, but it reduces its ability to be scanned omnidirectionally. So, more difficulty at the point of sale and fewer sales overall. The X-dimension, or the width of the narrowest bar in a 1D code, determines the ideal size of the symbol as, with each target x-dimension, there is a target height. In two-dimensional symbols, the X-dimension meanwhile corresponds to the height and width of one cell, meaning all cells should be the same size.

3. Create Barcodes on a Separate, Individual Layer

When creating barcodes for your packaging, it’s critical that you do so on a separate layer (one that includes all barcodes). If barcodes are created on the same layer as other elements, you run the risk of obstructing them. The end result would be increased difficulty detecting them, leading to other potential complications at the point of sale.

4. Keep the Barcode Text Legible

You don’t have to just worry about the branding information on your product packaging. The text below the barcode, or Human Readable Interpretation (HRI) of the encoded value, has to be made legible as well. That means in a clear font that’s proportional in size to the code. The reason why, when barcodes are typically scanned in, is simple: The HRI is the back-up. It can be typed in as a last resort in case the code is unreadable.

5. Choose the Right Color Combination

It’s downright logical but rarely considered before it gets to the point when you have to create and print the darn thing. That’s because when one thinks of barcodes, they tend to see the iconic black bars on white background. However, not all barcodes are printed on white labels. Some are printed directly on the packaging, which isn’t always white either. So, the color of the bars must compensate for the required high contrast, with the bars having to be the darker of the two elements. Otherwise, it may not get detected.

6. Use the Right Substrate (Material)

The readability issue surrounding the need for high contrast extends to the packaging material. As the code can be printed directly on (or marked into) the packaging material, the latter effectively serves as the background. As a result, the nature of the material is a big concern and not just relative to the color. Texture and reflectivity can have an impact as well.

Glossy materials combined with adverse lighting conditions can cause reflections and, subsequently, no-reads, while backgrounds with busy and inconsistent patterns, like metallic surfaces, run into similar problems. Proper lighting can compensate for issues such as these, but there’s little substitute for packaging material that’s uniform to begin with.

7. Quiet Zones Are Your Friend

Quiet zones, i.e., the white space around the symbols, are unheralded as a barcode element. After all, they’re technically not part of the barcode. They nevertheless have a positive impact when it comes to barcode readability. In fact, barcodes with inadequately sized quiet zones can fail to scan altogether, highlighting their importance.

The rule of thumb is for quiet zones to be at least 10 times the size of a one-dimensional barcode’s narrowest bar. For two-dimensional barcodes, the minimum border is said to be the size of one cell on each side of the symbol.

8. Placement, Placement, Placement

It’s not just about making the barcode easy to find when it’s placed on the packaging. It’s about making it as easy as possible for it to be detected.

Placing a barcode close to the cut and fold lines doesn’t just make it look cramped. It may cramp the barcode’s style to boot. Barcodes should ideally be placed 8 mm or more from either, so they don’t get inadvertently obscured or even damaged.

9. Properly Integrate an Entire Barcode System

If you’re going to go into the trouble of taking advantage of barcodes as most businesses do in this day and age, it makes sense to leverage them to their fullest capability. It’s relatively easy to generate one online or purchase them outright from a member of the global standards organization in charge of barcodes, GS1. It can be easy too (but admittedly overwhelming) to integrate an entire system, including all the necessary pieces of software.

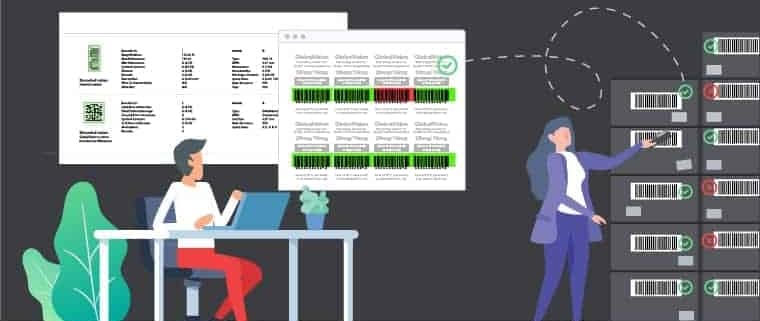

Even if you’re sending jobs to a print house, there’s a good chance you will need to create them yourself, using barcode label design software. Additional software that can come in handy? Barcode inspection software to ensure its readability in both digital and hard-copy formats and inventory software, with which you can scan barcodes to bring up individual product records (instead of just the number), track units, and manage orders.

10. Embrace the Future with RFID

Because of how ingrained in our culture barcodes have become, it’s easy to forget how much of a technological paradigm shift they represented when they were first introduced in 1974. And because barcodes were effectively designed to blend into the background, generally unnoticed as the visual equivalent of white noise so as not to distract from the packaging itself, it has become easy to take them for granted from a marketing standpoint.

That doesn’t mean they have actually been forgotten, though. In fact, even though you may not notice them, barcodes are gaining significant ground technologically speaking. For example, Digimarc barcodes are embedded in the packaging itself, which can be scanned just as if it were a traditional barcode.

Barcodes aren’t just for containing information reserved for the company anymore. By leveraging RFID (Radio-Frequency Identification) technology, companies allow customers to scan codes and access information directly aimed at them on their phones, including, but not limited to, marketing campaign videos or loyalty program offers.

Businesses still have the option to track inventory using RFID tags, making it arguably the next evolutionary step as far as barcodes are concerned. And it’s already here. Much like the barcode itself, it’s not a matter of if but when the phenomenon becomes widespread.

_________________________________________________________________________________________

Check out how GlobalVision can help with barcode inspection & quality control.